Update

Over time infrastructure needs to be evaluated for repairs and improvements. As the operator of three wastewater treatment plants that serve the needs of Municipal Utility Districts (MUDs) throughout The Woodlands, the San Jacinto River Authority (SJRA) began improving the Bear Branch Gravity Main wastewater collection system in early 2020. When completed, the structural integrity of the more than 2.5 miles of pipe and associated manholes in the Village of Cochran’s Crossing will be restored, preventing aquifer groundwater and stormwater from entering the collection system through possible leaking joints and manhole covers.

PROJECT UPDATE JULY 2020

SJRA’s construction contractor, SAK Construction, mobilized February 2020. Since then, SAK has installed:

- Temporary access roads so that the heavy equipment can reach all of the manholes and pipes to be rehabilitated.

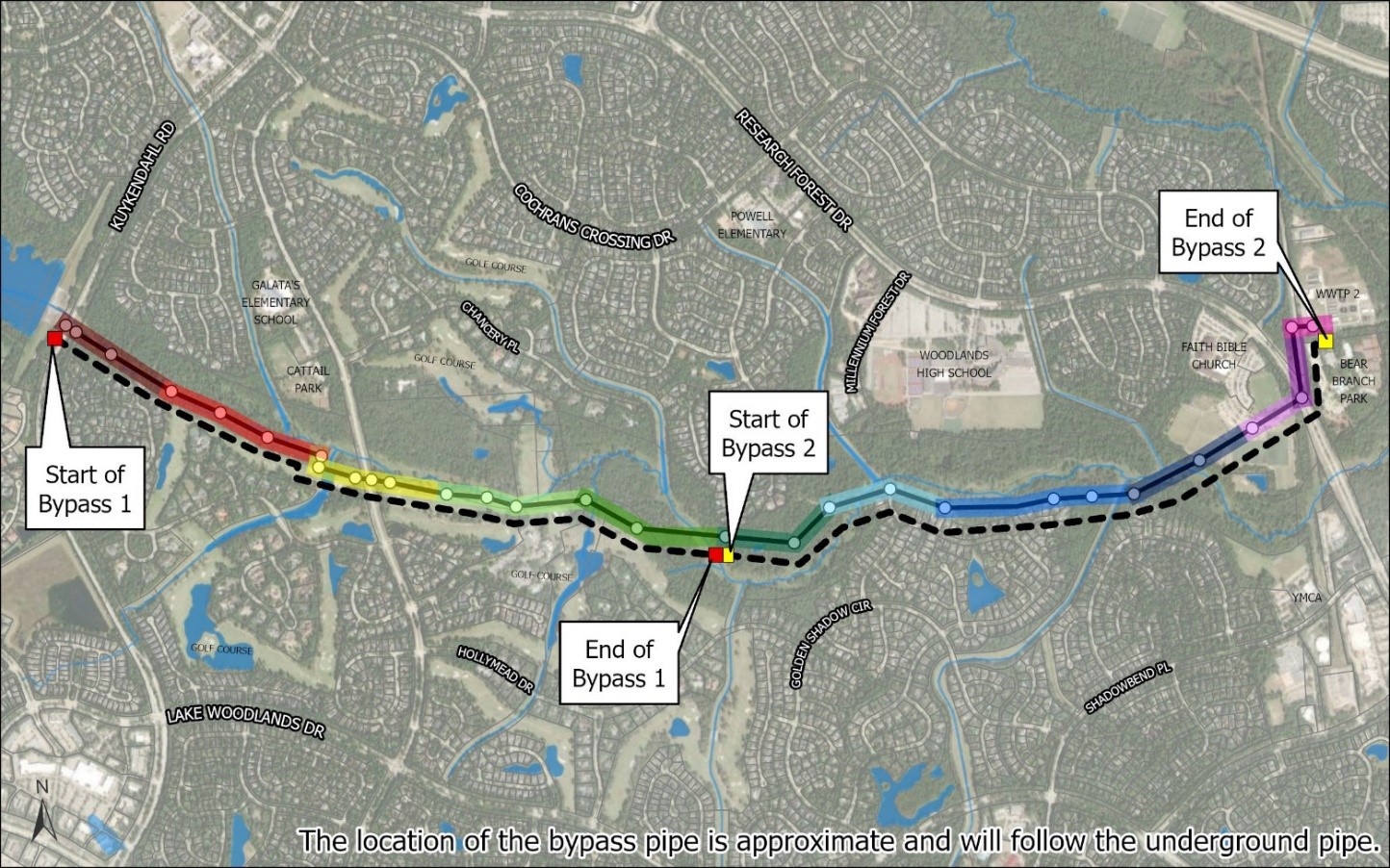

- The first of two bypass systems so that wastewater service remains uninterrupted while the project is completed.

SAK will begin a cured-in-place pipe (CIPP) lining process as well as manhole rehabilitation efforts. By using CIPP, SJRA will be able to significantly increase the life of our aging gravity sewer system in the most cost-effective manner that also reduces the construction schedule and impacts to the community. The CIPP process will be completed in smaller segments as shown below. SAK will be onsite 24-hours per day. Once the first half of the segments are rehabilitated, SAK will relocate the bypass to then start the second half of the project. Below is a map that identifies each segment, the two bypass pipelines, and the estimated construction schedule (dates subject to change).

What is Bear Branch Gravity Main? Why does it need to be rehabilitated?

The Bear Branch Gravity Main, a major sewer collection main for the SJRA Woodlands Division Wastewater Treatment Facility (WWTF) No. 2 service area, was installed in 1985, and requires rehabilitation based on physical condition assessments conducted in previous years. The gravity main is approximately 16,000 linear feet of existing 42-inch to 72-inches in diameter reinforced concrete sewer pipe.

What is Cured-in-Place-Pipe (CIPP)?

CIPP is a trenchless technology to rehabilitate and repair existing pipes without having to excavate or replace the pipes. It is a joint free, seamless pipe lining that is installed within the existing pipe. It is one of the most widely used rehabilitation methods for existing aging sewer lines.

What is the process for CIPP lining installation to rehabilitate the pipe?

- Divert existing sewer line flow by diversion pumps from one manhole to another.

- Mechanically clean and televise existing sewer line, remove debris, and check for failures.

- Mobilize trucks and equipment to a designated upstream manhole to receive the CIPP lining and at a downstream manhole that the CIPP lining will stop.

- The process of CIPP involves inserting and running a felt lining made of fiberglass into a preexisting pipe that is the subject of repair and rehabilitation. Resin within the liner is then exposed to a curing element (hot water) to make it attach to the inner walls of the pipe. Once fully cured, the lining now acts as a new pipeline.

- Because there are several different diameters of pipe within the pipeline, this process will be required to be repeated several times.

Why are there pipes laying on the ground?

In order to rehabilitate the gravity main system, the selected construction method requires that the existing system (underground sewer line) be taken out of service, in sections. The temporary above ground pipes will be used to bypass sections of the existing system while they are rehabilitated using CIPP.

What are normal construction hours?

Temporary access roads have been installed along the project route to allow the specialized CIPP equipment to access the pipes and manholes. Once the contractor starts the CIPP process, the crew will work 24/7 until that segment is complete. They will then move their equipment to the next segment to proceed with the next CIPP lining installation. There may be construction traffic on the access roadway during the night; however, if you see something suspicious, please report it to Montgomery County Sheriff’s Department at 936-760-5800.

Will there be noise, dust, or odors from the construction activities?

As with any construction, there may be activities that cause noticeable noises, but the contractor is required to minimize impacts to the neighboring communities. The contractor will mitigate dust impacts using water trailers as needed. Potential odors may be present in the vicinity of the where the bypass pipes are discharging into manholes and when the contractor is cleaning the existing sewer pipe in advance of installing the CIPP. The lining process may have a smell similar to nail polish.

Will the area be restored and temporary roads and water crossings be removed?

The current scope of work requires SJRA’s contractor to restore any areas impacted by construction activities. Planning and coordination between SJRA and The Woodlands Township may require some revisions to restoration activities.

When will this project be completed?

The project is currently anticipated to be complete by spring of 2021.

One of the major river authorities in Texas, SJRA’s mission is to develop, conserve, and protect the water resources of the San Jacinto River basin. Covering all or part of seven counties, the organization’s jurisdiction includes the entire San Jacinto River watershed, excluding Harris County. For additional information on SJRA visit our website at www.sjra.net, like SJRA on Facebook @SanJacintoRiverAuthority, follow us on Twitter @SJRA_1937, find us on Instagram @sanjacintoriverauthoritySJRA, or connect with us on LinkedIn @San Jacinto River Authority.